Background

I have wanted a 3D printer since I first saw one, but printers were not affordable enough for me until recent years. I love 3D CAD modeling of objects. Therefore, I always wanted to draw items in Solidworks and then print them into reality.

Printer Assembly

The instructions are kinda vague, but It takes about an hour to fully assemble. You assemble the top frame, x axis, and install the screen and wiring. The hardest part is determining which wire goes where when you don't know what are the X,Y,Z axis.

First Print

After I learned to level the print bed properly and read lots of instructions, I was off to slicing and printing. The first project was a cat for my daughter. It went pretty well actually.

Several Projects

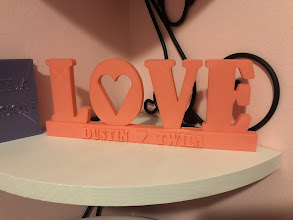

Here are some pictures of what I have printed. Some are my models and others are from other makers.

What I Have Learned

- There is a great gcode for bed leveling that will save you a lot of time.

- It is best to level the bed with hot-end and bed preheated

- Adjusting your z down a bit at each start may be required for good adhesion

- You need to set your temp correctly for each type of material. Some use a temperature tower for this but I like to print and adjust as needed. Also, Rolls come with a temp range on them.

- ABS is hard to print without warping on an open bed

- Join a group to learn from others' mistakes.

- The possibilities of what to print are endless

Want something printed?

Contact me if you want a 3d model or a 3D print.